Basic Info.

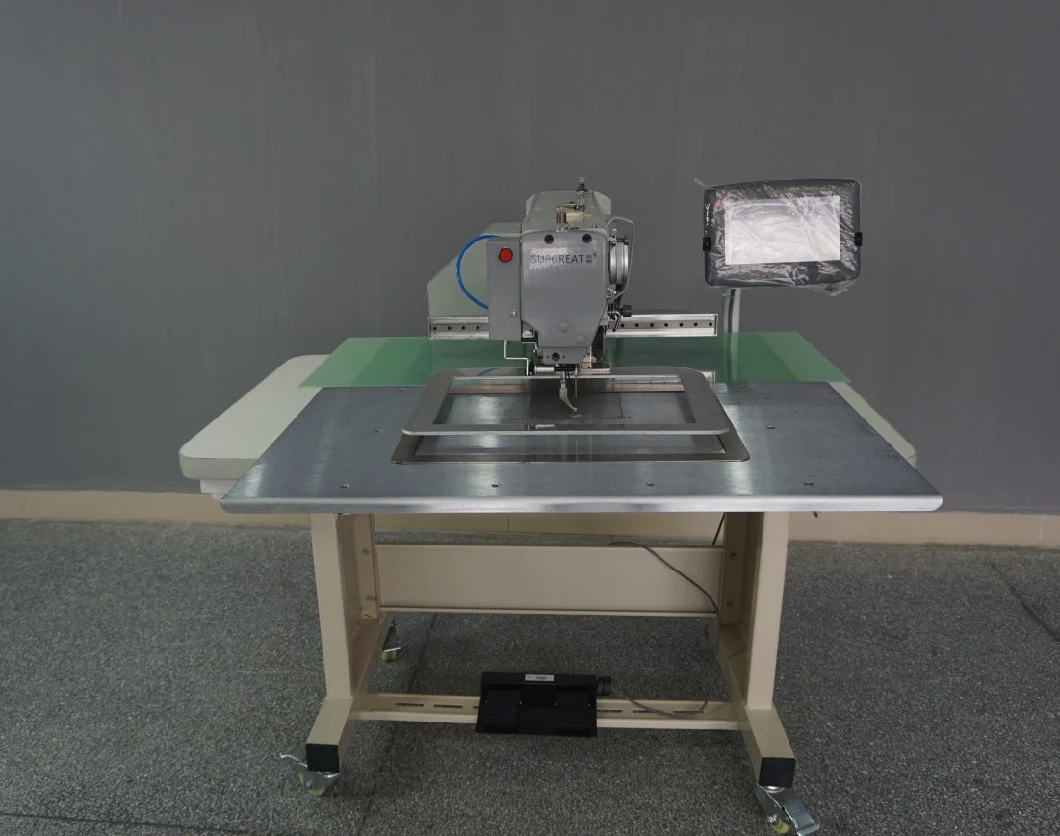

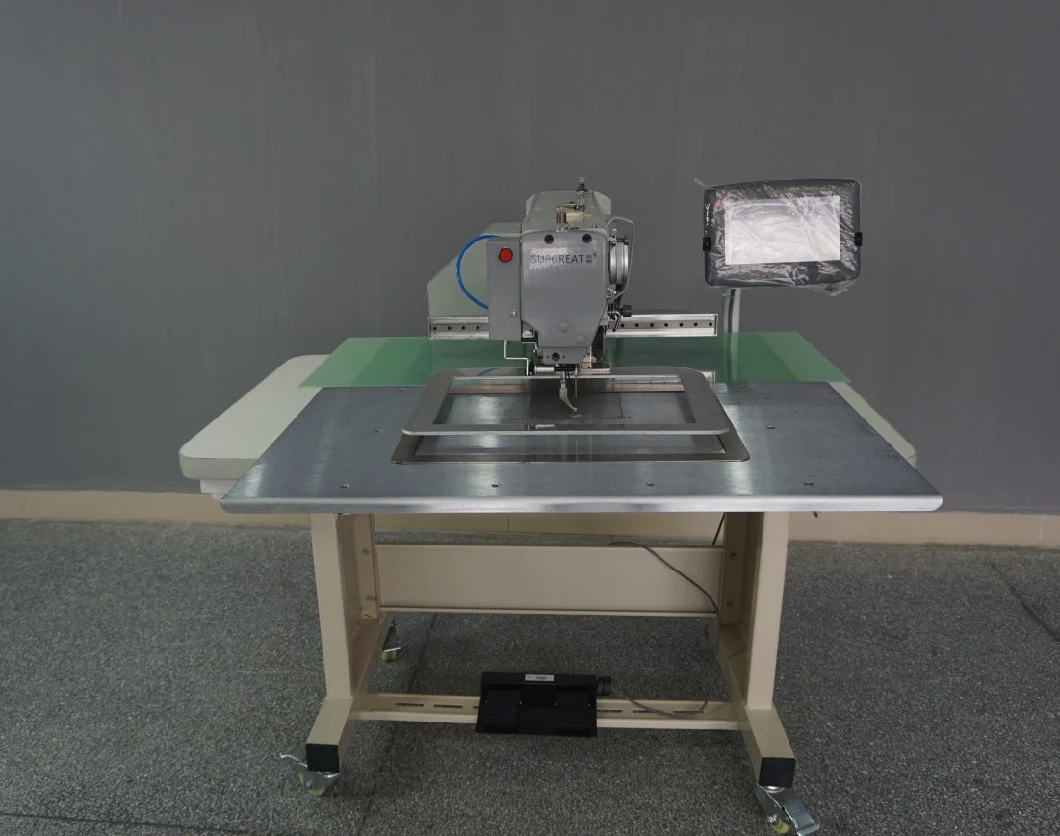

Model NO.

SR-3020AS-H

Drive

Electric

Thread Number

Single Thread

Needle Number

Single Needle

Stitch Type

Chain Type

Automatic

Yes

Sewing Area Device

300X200mm

Weigth

240kg

Motor

500W

Transport Package

Wooden Packaging

Specification

1200X1200X1300MM

Trademark

SUPREME

Origin

China

HS Code

8452219000

Production Capacity

50000PCS/Year

Product Description

You Might Also Like:

Thick Material Clothing Lockstitch Automatic Sideslip Industrial Electronic Garment Shoes Pattern Program Sewing Machine

Advantages :

-Programmable presser foot -Improve sewing quality

-Disconnection holding device -Oil-free head

-Low power consumption,high speed,high efficiency -Pattern edit quick and easy

-Strengthen needle penetration -Standard thread broken sensor

Automatic garment pattern sewing machine with the industry's fastest speed,efficient and beautiful sewing effect, wider sewing range ,stronger applicability,using energy-saving technology,the machine is more energy saving and environmental protection.

Famous products:

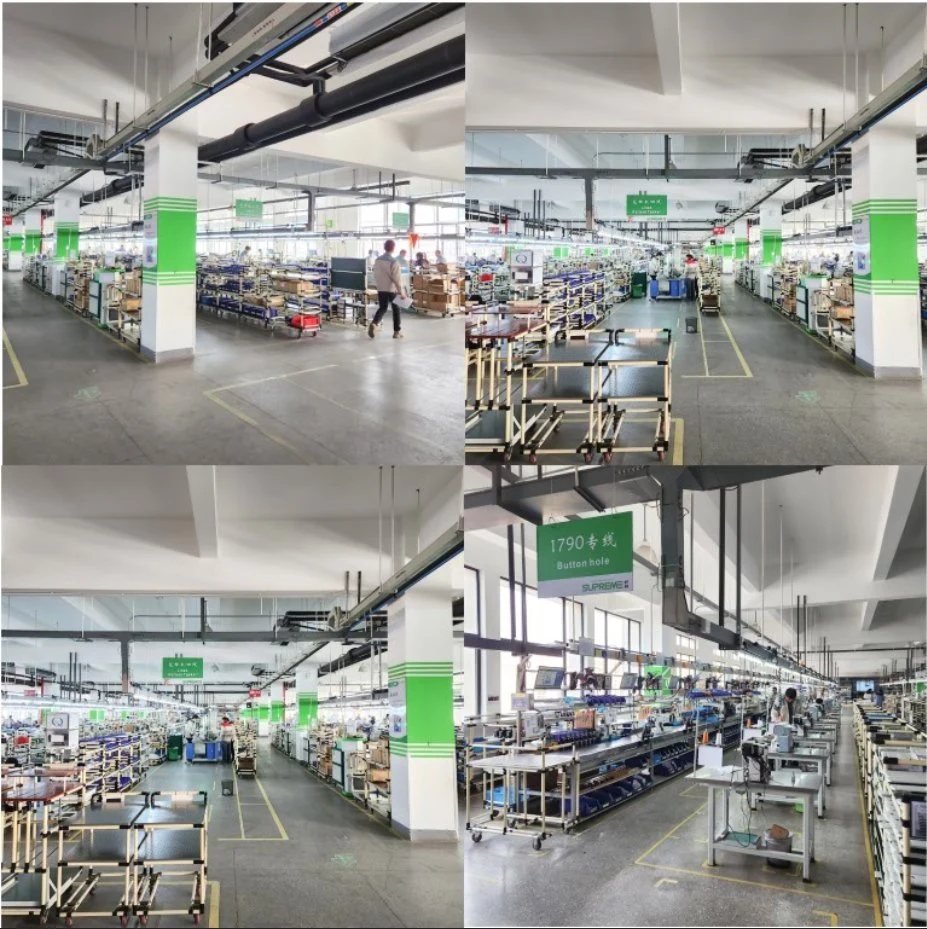

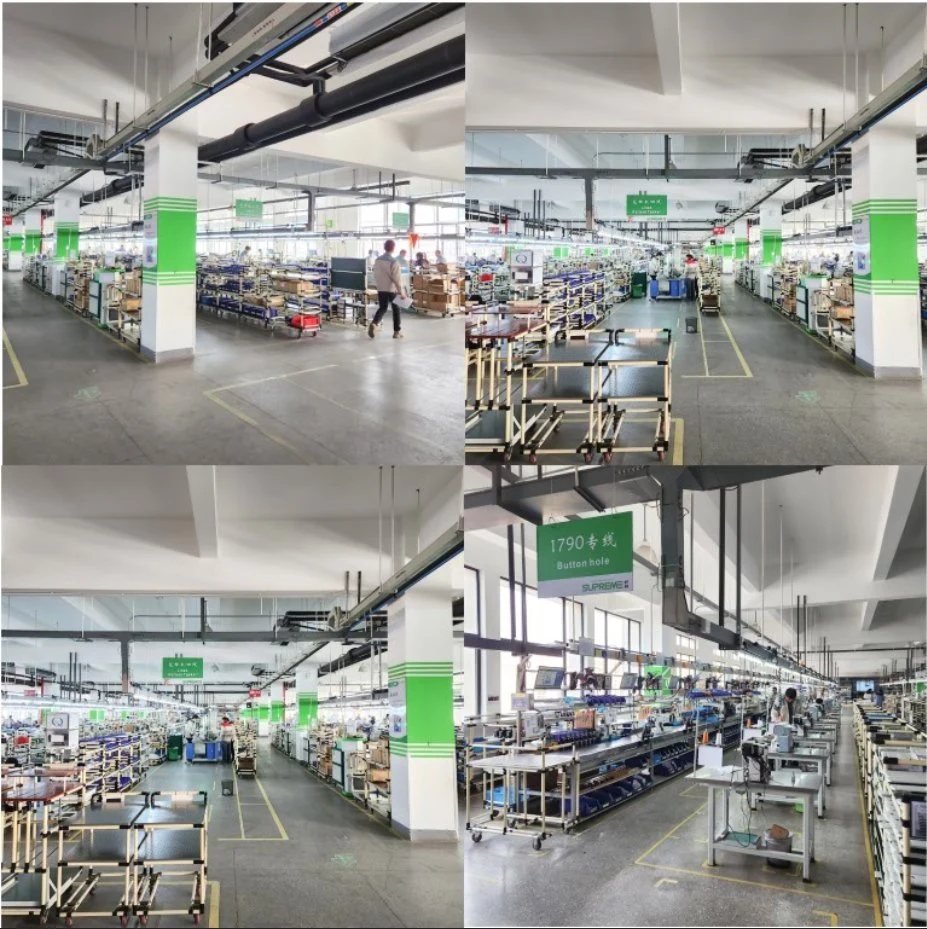

About us

Modern fashion industry has entered a customized and intensive development and the manufacture of the future fashion industry will be a technology-intensive and highly intelligent model ,the trend posing series of challenges against traditional manufacturing model. Supreme,' customer-focused ' ,focusing on customer needs , provides overall exclusive solutions for individual needs by supporting technological innovation.Special industrial sewing machine ,automatic sewing units and customized products: with strong R&D advantages ,through mechanic design ,motion control ,sound, light,visual control ,WIFI,RFID and other technologies,it achieved breakthroughs in the technological innovation of sewing machinery,using forward-looking vision and leading mind,which in return provides customers with high-quality and efficient products.Intelligent factory field : build an elite team of 100 people for the whole process of the smart factory, bringing together a group of professionals with deep industry background and rich practical experience. Based on self-develope CPS/PLM/QMS/WMS/APS/MES,core information system that perfectly integrated the IOT intelligent sewing equipment that in tegrate intelligent control technology.intelligent perception technology ,imagine recognition and sewing material motion control technology , so that materials and products have dynamic storage, perception, and communication capabilities. Through the real-time transmission and sharing of data, visualized process control and omni-directional system supervision are realized, so as to achieve intelligent self-management and self- organization of equipment, and self-monitoring and self-decision-making of flexible production.Equipped with an advanced intelligent logistics and warehousing system, it builds a highly energy-efficient, green and environmentally friendly humanized chemical factory, and continues to createmaximum value for customers.

Factory & production line:

Packaging & shipping:

FAQ

1,How long is your delivery time?

Usually it is 2-7 working days after the deposit time.The delivery time depends on the Customized Machine.,

2,How long is the warranty?

Our warranty time is 12months from date of machine arriving at your destination port.

3,Do you have any machine in stock?

Normally we have stock on most of the model.Some of special automation, Please kindly contact with us for

the delivery time.

4,Could you do OEM?

Yes,OEM is acceptable.We could make the unique machine as your specific configuration and requirements.

5,Why do you choose us?

Large factories from world famous brands are using our machine.Which is remarked as a company and machine

with High quality,Good service and Reasonable price.The Worldwide agents and professional after-Sale services

team will provide you perfect technical support.

Thick Material Clothing Lockstitch Automatic Sideslip Industrial Electronic Garment Shoes Pattern Program Sewing Machine

Advantages :

-Programmable presser foot -Improve sewing quality

-Disconnection holding device -Oil-free head

-Low power consumption,high speed,high efficiency -Pattern edit quick and easy

-Strengthen needle penetration -Standard thread broken sensor

Automatic garment pattern sewing machine with the industry's fastest speed,efficient and beautiful sewing effect, wider sewing range ,stronger applicability,using energy-saving technology,the machine is more energy saving and environmental protection.

| Line | Single-needle flat seam | |

| Highest sewing speed: | 2800rpm | |

| Sewing area device: | 300X200mm | |

| Cloth feeding device: | Intermittent feeding(driven by pulse motor) | |

| Stitch length: | 0.05-12.7mm | |

| Rising amount ofintermittent foot presser: | 22mm | |

| Stroke by intermittent presser foot: | 0 or 2-10mm(factory setting:3mm) | |

| Thread Wiper | / Standard facility | |

| Cutting device | / Standard facility | |

| Machine size | 1200X1200X1300MM | |

| Packing size | 1300x1300x1400MM | |

| Power | Single phase200~240V 3-phase 380V | |

| Weight | 240KG | |

| Air pressure | 0.5Mpa,1 .8L/ min | |

| Hook | double shuttle hook | |

| Data storage way | USB | |

| Motor | AC servomotor 550W | |

Famous products:

About us

Modern fashion industry has entered a customized and intensive development and the manufacture of the future fashion industry will be a technology-intensive and highly intelligent model ,the trend posing series of challenges against traditional manufacturing model. Supreme,' customer-focused ' ,focusing on customer needs , provides overall exclusive solutions for individual needs by supporting technological innovation.Special industrial sewing machine ,automatic sewing units and customized products: with strong R&D advantages ,through mechanic design ,motion control ,sound, light,visual control ,WIFI,RFID and other technologies,it achieved breakthroughs in the technological innovation of sewing machinery,using forward-looking vision and leading mind,which in return provides customers with high-quality and efficient products.Intelligent factory field : build an elite team of 100 people for the whole process of the smart factory, bringing together a group of professionals with deep industry background and rich practical experience. Based on self-develope CPS/PLM/QMS/WMS/APS/MES,core information system that perfectly integrated the IOT intelligent sewing equipment that in tegrate intelligent control technology.intelligent perception technology ,imagine recognition and sewing material motion control technology , so that materials and products have dynamic storage, perception, and communication capabilities. Through the real-time transmission and sharing of data, visualized process control and omni-directional system supervision are realized, so as to achieve intelligent self-management and self- organization of equipment, and self-monitoring and self-decision-making of flexible production.Equipped with an advanced intelligent logistics and warehousing system, it builds a highly energy-efficient, green and environmentally friendly humanized chemical factory, and continues to createmaximum value for customers.

Factory & production line:

Packaging & shipping:

FAQ

1,How long is your delivery time?

Usually it is 2-7 working days after the deposit time.The delivery time depends on the Customized Machine.,

2,How long is the warranty?

Our warranty time is 12months from date of machine arriving at your destination port.

3,Do you have any machine in stock?

Normally we have stock on most of the model.Some of special automation, Please kindly contact with us for

the delivery time.

4,Could you do OEM?

Yes,OEM is acceptable.We could make the unique machine as your specific configuration and requirements.

5,Why do you choose us?

Large factories from world famous brands are using our machine.Which is remarked as a company and machine

with High quality,Good service and Reasonable price.The Worldwide agents and professional after-Sale services

team will provide you perfect technical support.