- Overview

- Device parameters

- About Us

- Certificate display

- Visiting customers

- Packaging & Shipping

- FAQ

Basic Info.

Model NO.

KXT 3015

Object

Thread

Structure

Gantry

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Inlaid Tooth

Controlling Mode

CNC

Automatic Grade

Automatic

Precision

Precision

Certification

CE, ISO 9001

Condition

New

Model

Kxt 3015

Device Name

Gantry Milling Machine

X Axis

3200mm

Y Axis

1600mm

Z Axis

800mm

Gantry Span

1600mm

Distance From Spindle Nose to Table

150-1950mm

Table Size

1200*3000mm

Table Load

5000kg

Spindle Speed

3, 000(6, 000-Opt.)

Spindle Taper

Bt-50 / ISO-50 / Cat-50

Rapid Traverse(X/Y/Z)

6/10/7m/Min

Ball Screw Diameter(X/Y/Z)

63/50/50mm

Cutting Feedrate

6000mm/Min

Minimum Step Equivalent

0.001mm

Trademark

NORTH CRAFTSMAN

Origin

China

HS Code

8459611000

Production Capacity

300 Sets/Year

Packaging & Delivery

Package Size

380.00cm * 170.00cm * 150.00cm

Package Gross Weight

3000.000kg

Product Description

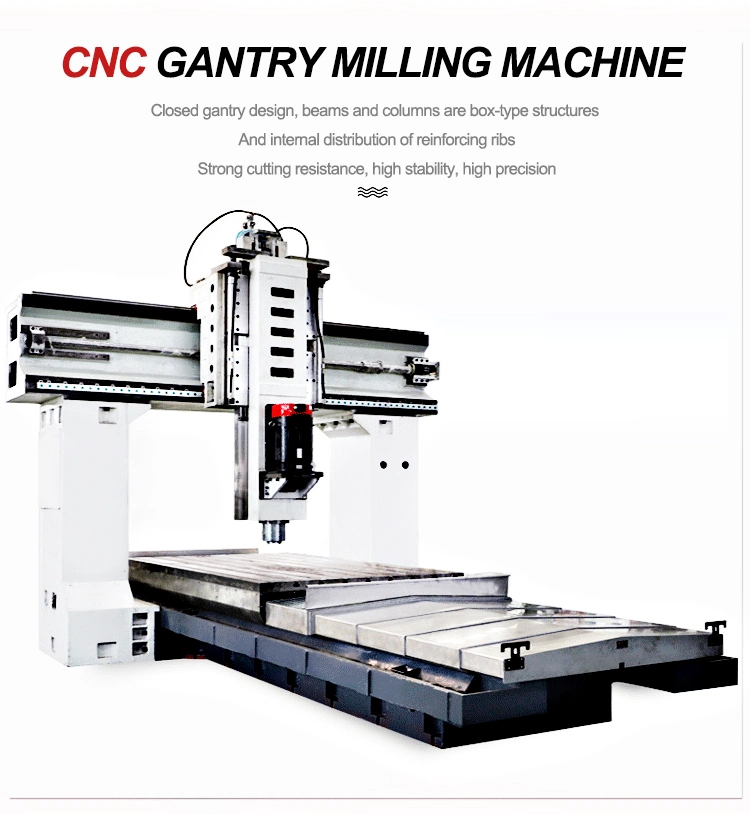

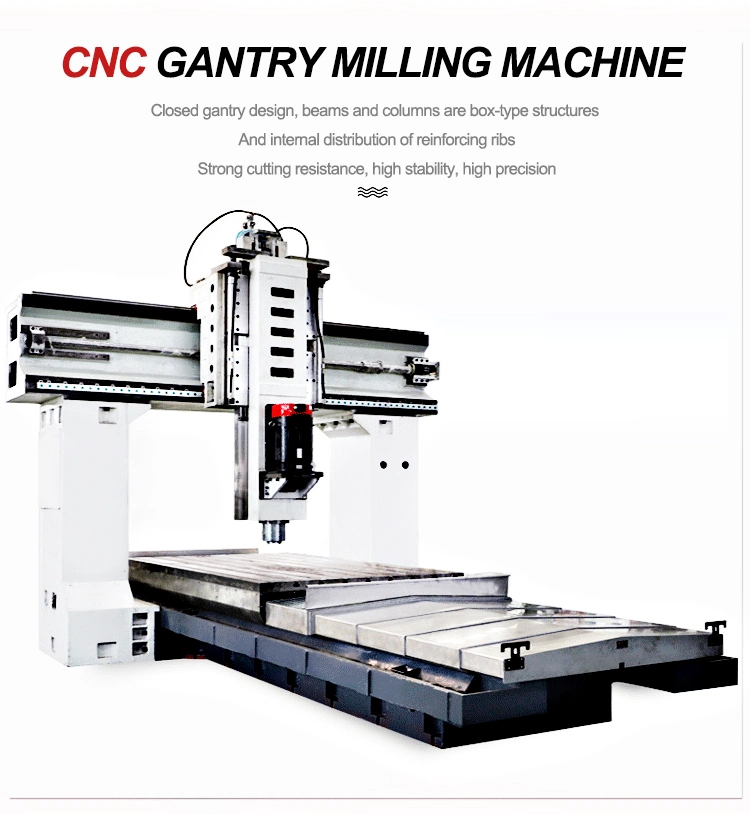

Gantry vertical horizontal machining center Gantry type CNC milling machine

CNC Gantry milling machine Vertical Gantry Machining Center

Double Column Machining Center Gantry milling machine

Gantry Machining Center 5 axis machining center cnc

CNC Gantry milling machine Vertical Gantry Machining Center

Double Column Machining Center Gantry milling machine

Gantry Machining Center 5 axis machining center cnc

The machine is widely suitable for general machinery, automobilem, aerospace, printing and packing, textile machinery, metallurgy, petrochemical, locomotive box line, mold and other large and medium-sized machinery parts processing and mould manufacturing, one-time can complete the rest of the five other than the mounting surface coarse, half finishing and finishing requirement, can finish milling, drilling, tapping, boring, reaming, and other process.

Adopt gantry frame fixed beam structure, machine bed and main parts use high-strength cast iron, ensure stability of the machine during long using term.

X/Y-axis adopt super overloading linear rolling guideway, Z-axis adopts rectangular hardened and plastic hard guideway;high-precision, high-speed, strong cutting and high rigid.

Spindle box is equipped with hydraulic automatic balancing system, balancing dynamically the self-weight of spindle box, guarantee processing accuracy and stability of the machine tool.

For high-precision and high rigidity and large-torque spindle unit, main transmission adopts gear speed shifting, high and low speed automatic transmission by hydraulic station, suitable for low-speed heavy cutting.

Adopt gantry frame fixed beam structure, machine bed and main parts use high-strength cast iron, ensure stability of the machine during long using term.

X/Y-axis adopt super overloading linear rolling guideway, Z-axis adopts rectangular hardened and plastic hard guideway;high-precision, high-speed, strong cutting and high rigid.

Spindle box is equipped with hydraulic automatic balancing system, balancing dynamically the self-weight of spindle box, guarantee processing accuracy and stability of the machine tool.

For high-precision and high rigidity and large-torque spindle unit, main transmission adopts gear speed shifting, high and low speed automatic transmission by hydraulic station, suitable for low-speed heavy cutting.

| Model | Unit | KXT1515 | KXT2016 | KXT3015 | KXT3020 | KXT4020 | KXT4025 |

| X axis | mm | 1500 | 2100 | 3200 | 3200 | 4200 | 4200 |

| Y axis | mm | 1500 | 1800 | 1600 | 2000 | 2200 | 2800 |

| Z axis | mm | 600 | 800 | 800 | 800 | 1100 | 1100 |

| Gantry span | mm | 1500 | 1600 | 1600 | 2000 | 2000 | 2500 |

| Distance from spindle nose to table | mm | 150-750 | 150-950 | 150-1250 | |||

| Table Size | mm | 1200*1500 | 2000*1250 | 1200*3000 | 1600*3000 | 1600*4000 | 2200*4000 |

| Table Load | Kg | 3000 | 5000 | 5000 | 8000 | 10000 | 15000 |

| T- Slot (Width x Number x Pitch) | mm | 22*5*160 | 22*5*250 | 22.5*7*250 | 22*7*200 | 22*7*220 | 22*9*220 |

| Spindle Speed | rpm | 3,000(6,000-opt.) | |||||

| Spindle Taper | - | BT-50 / ISO-50 / CAT-50 | |||||

| Spindle motor power | Kw | 11/15 | 15/18.5 | 15/18.5/22 | 18.5/22 | 18.5/22 | 18.5/22 |

| Spindle motor torque | N.m | 72/98 | 98 | 98/117/140 | 117/140 | ||

| Rapid Traverse(X/Y/Z) | m/min | 10/10/7 | 6/10/7 | ||||

| Servo motor power(X/Y/Z) | Kw | 5.1/3.6/4.7 | 5.2/3.6/4.7 | 5.5/4.7/5.1 | 7.5/4.7/5.5 | 7.5/4.7/5.5 | 7.5/5.5/5.5 |

| Servo motor torque(X/Y/Z) | N.m | 27/18/23 | 28/18/23 | 32/23/27 | 36/23/27 | 36/23/27 | 36/27/27 |

| Servo motor speed(X/Y/Z) | rpm | 2000 | |||||

| Ball screw diameter(X/Y/Z) | mm | 50/50/50 | 63/50/50 | 80/50/50 | 80/63/50 | ||

| Cutting feedrate | mm/min | 6000 | |||||

| Minimum step equivalent | mm | 0.001 | |||||

| Standard Accessories | Optional | |

| 1 | KND/SYNTEC CNC system | FANUC/SIEMENS CNC system |

| 2 | Direct-connected spindle speed is 3000rpm | Gear-type spindle speed is 6000rpm |

| 3 | Both sides of screw chip removal device | Belt-type spindle speed is 6000rpm |

| 4 | Spindle with two-stage speed change box | Disc-type tool magazine |

| 5 | Electric tank with air condition | Chain-type tool magazine |

| 6 | Air filtration purification device | Vertical and Horizontal tool magazine |

| 7 | Spindle oil cooler | CNC rotary table |

| 8 | Cooling device | Grating scale |

| 9 | Hydraulic system | Water gun |

| 10 | Air gun | Accessory head grabbed automatically |

| 11 | Machine protection shield | Attachment head loss prevention system |

| 12 | Linghting system | Fully-auto. 90 degree milling head |

| 13 | Three color light alarm | Semi-auto. 90 degree milling head |

| 14 | Cutting blow | Manual 90 degree milling head |

| 15 | Communication interface | Extended milling head |

| 16 | Handheld electronic hand wheel | Side milling head |

| 17 | Tools and tool box | Flat right-angle milling head |

| 18 | Horizontal adjustment bolts and shim | Column heightening |

| 19 | Technical documents | Z-axis travel is 1250mm/1500mm |

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2. Can we pay by L/C or others ?

Yes ,you can make the payment by T/T , l/C etc.

3. What is your payment terms ?

30% down-payment after contract ,and 70% payment before shipment,

Meanwhite it can be discussed according to your situation.

4.When is the delivery time?

The delivery depends on different machines with different configurations.

Please contact us to confirm it is in stock or not.

5. How to handle the warranty period?

During the warranty period, we will provide free replacement parts (EXW)

which are easy damaged.

If the machine problem is not belonging to our machine quality problems,

when the buyer needs us send engineers to give repairing service, we charge

the appropriate cost.

6.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer's installation site, we timely send mechanical and electrical

engineers to install according to the buyer's schedule, the buyer undertakes board and lodging

of personnel abroad in the process of installation, and also USD50.00-100.00 per day per person.

The seller will cooperate with the buyer to deal with visa and installation preparation before

going abroad.

MOQ is one set, and warranty is one year.

2. Can we pay by L/C or others ?

Yes ,you can make the payment by T/T , l/C etc.

3. What is your payment terms ?

30% down-payment after contract ,and 70% payment before shipment,

Meanwhite it can be discussed according to your situation.

4.When is the delivery time?

The delivery depends on different machines with different configurations.

Please contact us to confirm it is in stock or not.

5. How to handle the warranty period?

During the warranty period, we will provide free replacement parts (EXW)

which are easy damaged.

If the machine problem is not belonging to our machine quality problems,

when the buyer needs us send engineers to give repairing service, we charge

the appropriate cost.

6.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer's installation site, we timely send mechanical and electrical

engineers to install according to the buyer's schedule, the buyer undertakes board and lodging

of personnel abroad in the process of installation, and also USD50.00-100.00 per day per person.

The seller will cooperate with the buyer to deal with visa and installation preparation before

going abroad.