Basic Info.

Model NO.

HN1600P

Type

Roll Slitter

Work Method

Flat Knife Slitting

Structure

Frame Part

Packaging

Case

Classification

Film Slitting

Applicable Process

Final Inspection

Suitable Substrates

Film Cutting

Packaging Material

Exporting Wooden Box

Speed

500m/Min

Slitting Width

1300mm

Tension Control

Automatic

Blade

Shavor Blade

Rewinding Shaft

Slipping Air Shaft

PLC

Mitsubish

Servo Motor

Taiwang

Mini Slitting Width

30mm

Transport Package

Standard Exporting Wooden Box

Specification

1300mm

Trademark

HAVESINO

Origin

China

HS Code

8441100000

Production Capacity

20PC/Month

Packaging & Delivery

Package Size

340.00cm * 280.00cm * 170.00cm

Package Gross Weight

5000.000kg

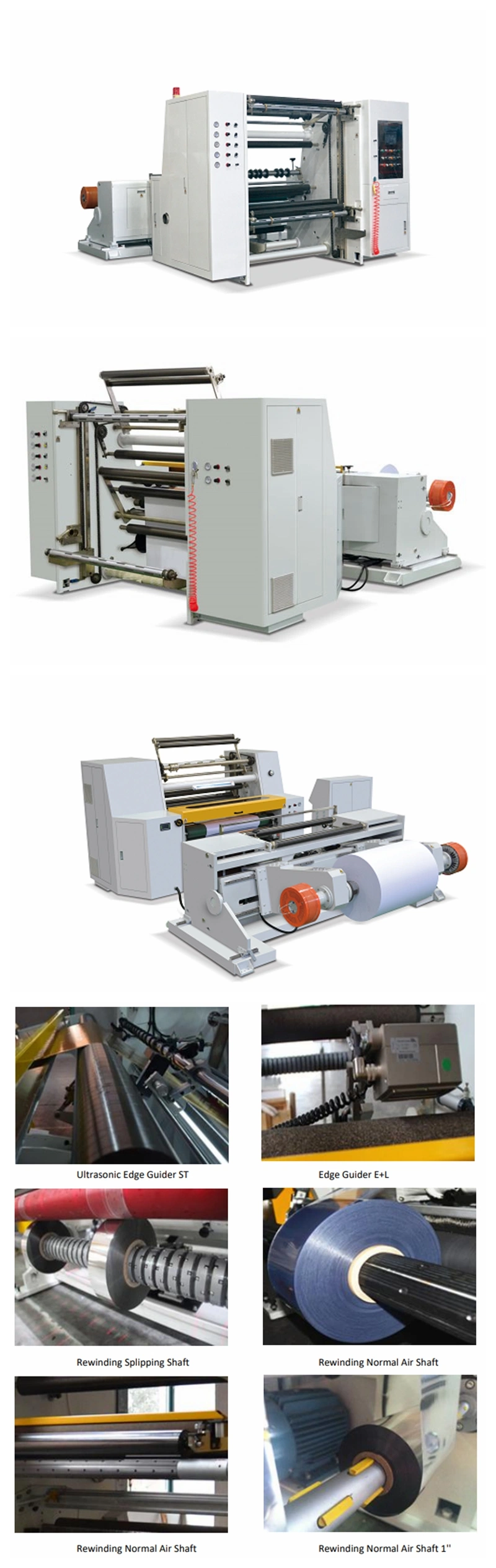

Product Description

Paper Craft Roll Adhesive Label Cup Bag Fabric Silicon Jumbo Lamination Box Sticker Nonwoven Ticket Thermal Paper Tape Slitting Machine Slitter Rewinder Cutter

Automatic Tenstion Control

High-Speed PLC Controlled Paper Slitting Machine

HN1600P

HAVESINO Materials to machine

Click one to know more

HN1600P

APPLICATION Automatic Tenstion Control

High-Speed PLC Controlled Paper Slitting Machine

HN1600P

HAVESINO Materials to machine

Click one to know more

HN1600P

A. 40-500gram PAPER/LABEL/ADHESIVE LABEL

B. Non-Woven FABRIC

C. 30-180um PRIMARY FILM (BOPP,PVC,LDPE,PET,SINGLE SILICON FILM and so on)

D. 30-180um LAMINATES (FILM to FILM,FILM TO FOIL,FILM TO PAPER and so on)

AND OTHER MATERIAL (PlS CHECK WITH THE SALES MANAGER)

FEATURES

A. Auto Tension Control;

B. Easy Installing and Quick Operation Learning;

C. 24*7 Hours Online Service;

D. Stable Performance and Long Life Use ;

E. Very Cost Effective Slitter in China;

F. Precise Slitting, Fast Speed, Perfect Edge Slitting

HN1600P big diameter rewinding slitter is specially design for large rolling materials, such as PET, BOPP, PE, paper sticker, paper, compound printing paper and so on. It is a very cost effective slitter in China.

BASIC INFORMATION

| 1 | SLITTING WIDTH | 300MM ~ 1600MM |

| 2 | SLITTING THICKNESS | 40-500GRAM and 30-250 MICRO METER |

| 3 | UNWIND DIA. | MAX1500MM OPTIONAL 1600MM |

| 4 | UNWIND CORE I.D. | SHAFTLESS 3 INCH AND 6 INCH |

| 5 | REWINDING DIA. | MAX 800MM |

| 6 | REWINDING WIDTH | MINI 40MM |

| 7 | REWINDING CORE I.D | NORMAL AIR SHAFT OPTIONAL SLIPPING AIR SHAFT |

| 8 | SLITTING UNIT | SHEAR CIRCLE BLADE 10 PCS |

| 9 | MECHANICAL SPEED | MAX450M/MIN |

| 10 | WORKING SPEED | MAX350M/MIN |

| 11 | MACHINE FRAME THICKNESS: | 50MM |

| 12 | METER COUNTER: | METER COUNTER |

| 13 | WASTE EDGE UNIT: | AIR BLOWER |

| 14 | POWER SOURCE | 380V,3 PHASE 4 WIRES,50Hz OPTIONAL: AS PER CUSTOMER |

| 15 | PNEUMATIC SOURCE | 0.8MPA |

| 16 | LASER POSITIONING | 10 PCS |

| 17 | MACHINE SIZE (REF. ONLY): | 3400mm(not including unloading frame tree)×3300mm×1800mm |

| 18 | FLOOR SPACE(REF.ONLY): | 4200MM*3300MM |

| 19 | N.W (REF. ONLY): | 4500KG |

FUNCTIONAL DESCRIPITION

Unwinding Unit:

- Adopts automatic cylinder loading. Magnetic brake. Automatic tension

- It does not need to input the material thickness, the proximity switch can inspect the unwinding diameter directly which near the transmission shaft. The machine can slow down according to the rest material, in this way, the worker can prepare for the next roller

- With the manual adjustment system, the unloading material tightness can be controlled. The adjustable range: +/-20mm

- Adopt thread screw to move the frame left and right by motor to make the auto error-correction.

- Corridor type feeding materials easily for operation

- Magnetic powder:20KG Brake: 2sets

Traction Unit:

- The 7.5 KW servo motor drives the mirror surface and pinch roll

Waste Paper Recycle Device Unit:

- Using motor to blow out the waste paper. The net cage should be prepared by customer.

Rewinding Unit:(Automatic Loading and Discharging, Easily for Operation)

- Rewinding the cut material by upper and bottom double bearing

- Each rewinding shaft with 1 set of 11KW servo motor to drive the air shaft. The tension decided by the roll diameter. PLC controls SMC electric automatically to make all the sheet same thickness when do the multiple slitting. Because of the press roller, all the reels end face is smooth. it has the choice of pneumatic press roller and self-weight press roller. The screw type rewinding way can control the degree of the tightness of the finished products. With the increasing of the rewinding diameter, the servo motor speed goes down to extend the life of the air shaft

- The air shaft never broken except the human factor

- It can choose the whole shaft tension without friction and the servo motor in torque control mode in PLC

- Rewinding and discharging: automatic up and down

- Full Width Pressing Rollers with pneumatic control to ensure the finished roll surface keep smooth;

GUARANTEE AND SERVICE

1) Before ship the slitter and rewinder, we will make a 100% fully test.

During the test time, you can give us your idea how to test, we can make the test as per your requirement.

We also can make a online live test to show you to ensure you have no doubt for the slitter rewinder.

After the test, both of us can enusre the slitter and rewinder has no any problem;

2) We ship the slitter and rewinder with whole part.

A very good packaging, like attached picture,to ensure the land and sea transport has no problem.

When the slitter and rewinder arrive, you can quickly start it after power and air connection.

3) We will establish a wechat group, our engineer will be in this chat group.

We provide 7*24H service during the time you installing and start to use the slitter and rewinder.

This ensure that any problems will be solved immediately to save your time;

4) We also have some cooperation agent in Spain.

If you need a assistance, we can ask them to visit you to help you install or solve the problem you meet.

5) All the main parts of the slitter and rewinder are provided 1 year guarantee.

We can arrange to send out the spare parts within 1-2 days by courrier during the gurantee.

( But as per our experience, if there is no problem for the first month of the slitter and rewinder, the main parts has no problem for whole life.)

6) Each year, we have 1-2 tims Europe travel.

We provide site inspection for all our slitter rewinder, to ensure our customer use the slitter rewinder in right and good way.

We checks the condition of the machines, and give you some suggestion of maintance.This service is totally free.

7) We provide upgrade service for both hardware and software,this service is also free.

After many years use, we also provide the service to upgrade or modify for the old slitter and rewinder.

8) If you like to be our reference company, and can accept our potential customer visit and look, we can pay the commission for each successful order.

As a exprienced and more than 12 years slitter rewinder professional manufacturer and provider, we have much more exprience to solve any problem.

About Havesino

HAVESINO is one of top suppliers for Semi Automatic and Fully Automatic thermal paper slitter re-winders and converting machinery for more than 12 years. We have in excess of hundreds of machine installations all around the world!

HAVESINO is one of the leaders in design, developing and building of quality,high performance of thermal paper slitter re-winders and the support machine such as core loader, core-less machine and fully automatic packing lines.

HAVESINO is one of the leaders in design, developing and building of quality,high performance of thermal paper slitter re-winders and the support machine such as core loader, core-less machine and fully automatic packing lines.