Basic Info.

Model NO.

SDX-cleanroom wipes roller

Color

White&Blue

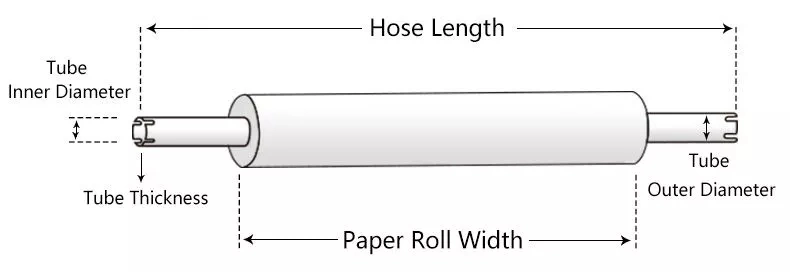

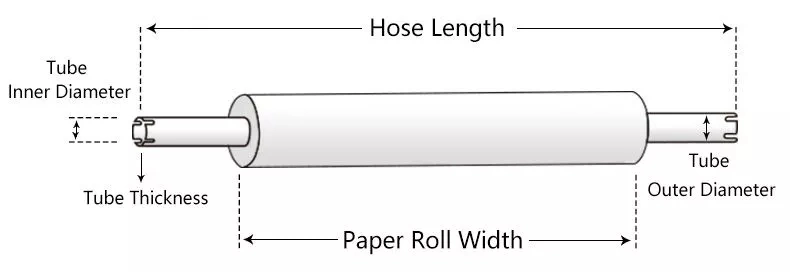

Size

50cmx30m or Customize

Composition

Wood Pulp, Polyester

Certficate

ISO14001

Clean Grade

Class 100

Weight

50g~68g

MOQ

100 Rolls

Transport Package

Carton

Specification

4 rolls/ carton

Trademark

OEM

Origin

China

HS Code

4823909000

Production Capacity

20000 Rolls/ Day

Product Description

Dust-free Cloth Absorbent Oil Industrial Wipes Paper Roll for Cleaning Room

Advantage:

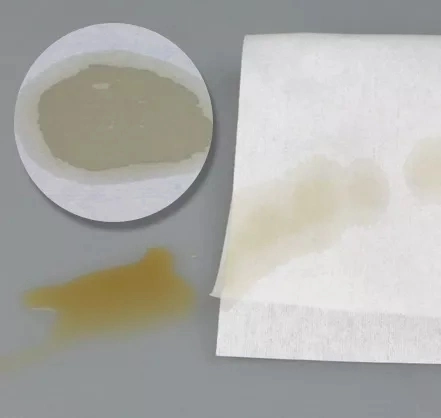

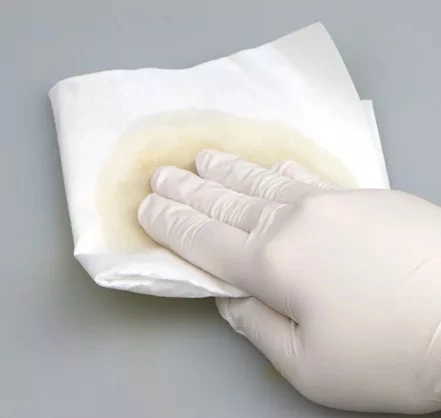

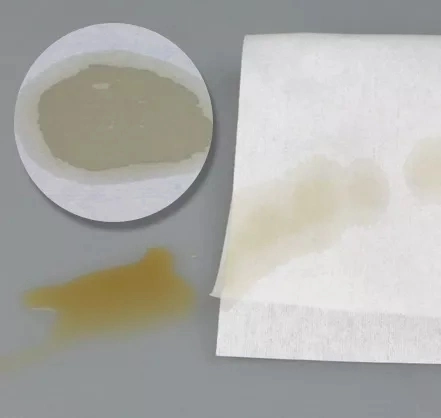

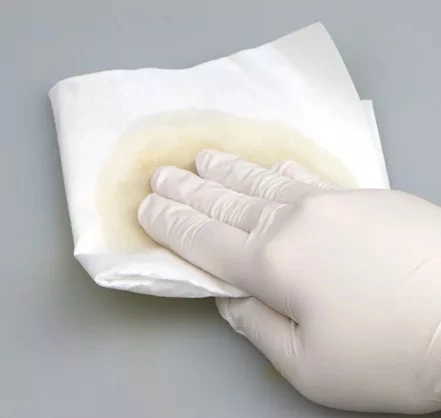

The large roll of industrial wipes uses a technology that uses natural wood pulp and polyester fiber as raw materials to form a wood pulp/polyester double-layer structure, which is strong and durable, has high water and oil absorption, is soft and does not drop dust. The cleaning effect is good, and it has good absorption performance for water, oil and other solvents, and can quickly absorb water, oil and other liquids, improving labor efficiency.

Features:

1. As a wipe paper for daily cleaning and wet liquid agent

2. High humidity in both dry and wet state

3. Can be used multiple times

4. It is economical and clean, and is a widely used wipe paper in the electronics industry

5. Strong moisture absorption, strong cleaning function, soft and wear-resistant, low dust generation rate, heat sealing edge, corrosion resistance, double bag dust-free packaging.

Basic use:

Wipe oil, liquid, wipe and clean sealant, suitable for procedures that have some basic requirements for dust-free performance, cleaning and maintenance of various mechanical equipment, and maintenance of mechanical processing center equipment.

Product Display

Product Details

Advantage:

The large roll of industrial wipes uses a technology that uses natural wood pulp and polyester fiber as raw materials to form a wood pulp/polyester double-layer structure, which is strong and durable, has high water and oil absorption, is soft and does not drop dust. The cleaning effect is good, and it has good absorption performance for water, oil and other solvents, and can quickly absorb water, oil and other liquids, improving labor efficiency.

Features:

1. As a wipe paper for daily cleaning and wet liquid agent

2. High humidity in both dry and wet state

3. Can be used multiple times

4. It is economical and clean, and is a widely used wipe paper in the electronics industry

5. Strong moisture absorption, strong cleaning function, soft and wear-resistant, low dust generation rate, heat sealing edge, corrosion resistance, double bag dust-free packaging.

Basic use:

Wipe oil, liquid, wipe and clean sealant, suitable for procedures that have some basic requirements for dust-free performance, cleaning and maintenance of various mechanical equipment, and maintenance of mechanical processing center equipment.

| SMT Stencil Wiper Roll | |||

| Item Name | Cleanroom SMT Stencil Cleaning Wipe Roll | ||

| Material | Polyester + wood pulp | ||

| Color | White | ||

| Feature | Strong cleaning power, good flexibility, strong liquid absorption | ||

| Size(width* length*core diameter) | 350mm*18m*20mm or customized | ||

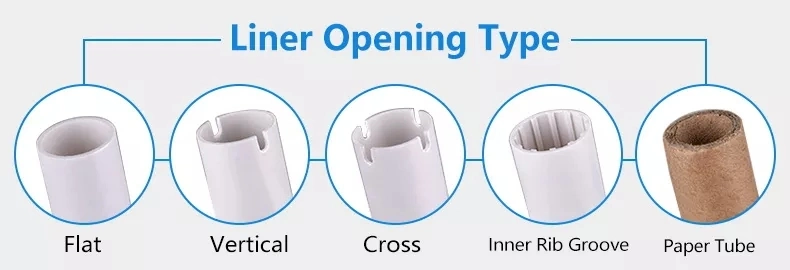

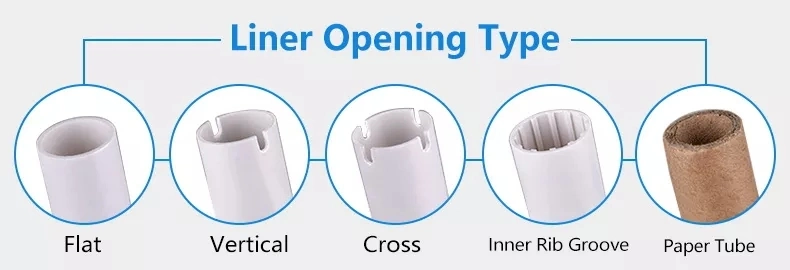

| Core material | Brown paper/ PVC | ||

| Machine model | MPM, DEK, SANYO, EKRA, MINAMI, PANASENT | ||

| Cleaning grade | Class100-10000 | ||

| Weight | 68g /m2, 65g /m2, 60g /m2, 55g /m2, 50g/m2 | ||

| Usage Field | SMT production line/ semiconductor assembly production line/ optical products/ PCB products/ automobile/mobile/ phoneproduction line/ medical equipment. | ||

| MOQ | 100 rolls | ||

Product Display

Product Details

1.  ......................................................

......................................................

Wood pulp and polyester material combined with polyester Fiber, through a unique spunlace method Processed, with a double-layer structure Fast liquid absorption speed, does not leave after wiping Drop particles and threads, both dry and wet For use, the cleaning effect is good.

Good solubility resistance, paper can Use with various clear solutions.

Good solubility resistance, paper can Use with various clear solutions.

1. Clear Texture Easy to wipe with water

Wood pulp and polyester material combined with polyester Fiber, through a unique spunlace method Processed, with a double-layer structure

......................................................

2.

High-Efficiency Water Absorption

High-Efficiency Water Absorption

............................................................

......................................................

3.

Tensile Resistance

......................................................